Easy accessibility to all parts and lubricating points for regular and fast upkeep has been provided maximum value in design. All products used tend to be of correct and certain grades as they are properly tested.

Type & Model

'Speedcrafts' Bitumen mobile phone hot-mix Plant, Model SBM-10, ability 6/10 mt. per hour, generally conforming to IS:5890.

Power Device

Run on Simpson S4(we) / Kirloskar RB-33 water-cooled diesel motor establishing 41.5/37.5 bhp @ 1500 rpm with 12 V electric starting arrangement. The system is fitted with a power take-off clutch and decrease gear field.

Feeder

a bucket elevator is provided, which discharges aggregate into the drying out cylinder through the feeding band.

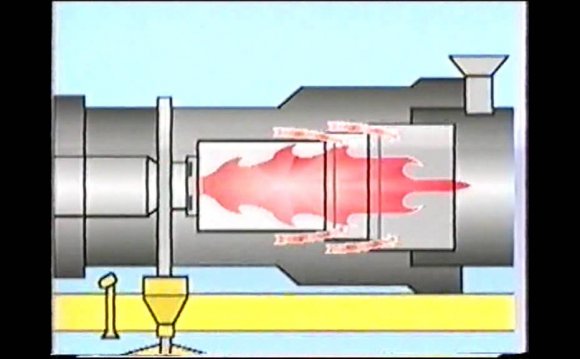

Drying Out Cylinder

The drying out cylinder is 2 mtrs. in total as well as 0.70 mtrs. diameter and it is fitted with replaceable lifting flights. It discharges heated aggregate into the storage band. It really is supported on two roller tracks operating on 4 nos. guide rollers and is driven by chain and sprocket wheel.

Aggregate Burner

A single burner, having approximate fuel use of 28 ltrs./hr. is equipped into release end associated with the drying cylinder. The gasoline consumption depends upon the health of the aggregate. A fuel pump is given to feeding fuel and environment is supplied by way of an air blower.

Air Blower

It's driven by the motor through a v-belt and is of ideal convenience of the burners supplied.

Storing Ring

The storage space band is fixed on discharge end of drying cylinder and it is fitted with lifting buckets which discharge the hot aggregate in to the batching chute.

Batching Chute

The batching chute is suitably designed and has now a set volume. The discharge of hot aggregate from chute to paddle mixer is by means of a lever which holds completely two businesses simultaneously- it opens up the radial door for discharging the aggregate to the paddle mixer as well as closes a deflector plate near the top of the chute to avoid any material becoming released to the chute although the radial door is available. A thermometer is supplied to register the heat associated with stone into the chute.

Drum Hoist

a cable rope hoist receives lifting framework for easy and convenient loading of bitumen from drums to the boiler.

Bitumen Boiler

The bitumen boiler is of adequate capacity and is provided with a burner and suitable heating arrangement to stop the bitumen from catching fire.

Air is supplied through the blower. Molten bitumen is lifted through a bitumen pump through a pipeline into the bitumen bucket. Approximate gasoline use of the bitumen burner is 11 ltrs./hr.

Bitumen Feed Pump

A bitumen pump will get the bitumen boiler. It really is driven by chain and sprocket from the line shaft.

Bitumen Bucket

A calibrated bucket is provided in which the molten bitumen is collected for discharge, as needed, into the pugmill. The quantity of bitumen could be metered through a 3-way dick connection.

Mixing Drum

The aggregate and bitumen are combined in another paddle mixer kind drum, fitted with two paddle shafts mounted with arms and recommendations which rotate in other guidelines. The shafts tend to be gear driven and attached to lubricated gunmetal bushes. The paddle ideas are covered with special difficult facing alloy to provide all of them longer life in operation and generally are additionally replaceable. This arrangement provides good mixing and provides a homogenous blend. The items are released through a door at the bottom which can be run by a hand lever.

Chimney

A chimney is provided to attract out the hot gases. A sliding door can be fitted which collects the good dust within the chimney package. This dirt might provided back into the feeder. To facilitate transport, the chimney could be collapsed.

Framework

Your whole product is mounted on a powerful chassis of welded and bolted building with rolled and collapsed metallic parts and fitted with 4 nos. pneumatic tyres. Four powerful technical parking jacks tend to be fitted to the framework.