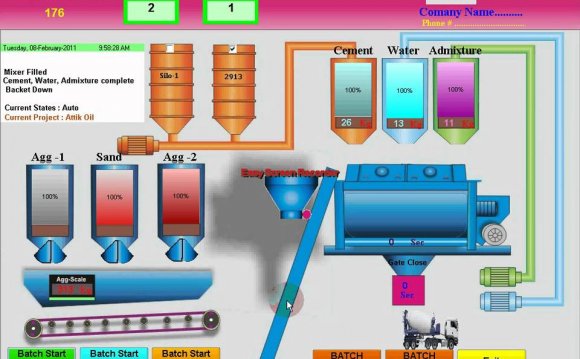

An EPIC batch mixing system automates highly accurate ingredient additions. EPIC Engineers focus our batch blending systems for product repeatability and consistency. Our systems often use mass flow meter charging to reduce batch cycle times, allowing concurrent raw material addition.

An EPIC batch mixing system automates highly accurate ingredient additions. EPIC Engineers focus our batch blending systems for product repeatability and consistency. Our systems often use mass flow meter charging to reduce batch cycle times, allowing concurrent raw material addition.

Powdered or liquid ingredients may be blended together using techniques that far surpass standard, off-the-shelf batch mixers. EPIC can design and fabricate batch mixing systems for even the toughest chemical mixing applications. The process technology can involves hard products in various elemental states like high viscosity liquids, non-Newtonian fluids, hygroscopic powders, or hygroscopic materials. Contact an engineer today to start designing your custom batch mixing or batch blending system.

Multi-Skid Sanitary Batch Mixing Module

A multi-skid batching plant process for water, fragrances, antibacterial and dust control chemicals was designed and integrated for a Fortune 100 pet care client. The sanitary USP grade tank mixing system was designed as a series of modular skids. The platform and modular design allowed easy access to chemical batching skids, equipment and system controls.

Key Features: Batch mixing systems, USP grade system, modular skid, antibacterial, dust control chemicals.

Key Features: Batch mixing systems, USP grade system, modular skid, antibacterial, dust control chemicals.

An automotive parts client required a flexible chemical mixing system for 100+ formulas for treatment dips. EPIC integrated the intricate multi-stage batch mixing control system, complete with a high level of communications, for real time changes and continual improvement. The system improved mixing and tracking ability through the batch controller and desktop recipe editor/batch scheduler. Read more about the industrial batch mixing system for 100+ formulas…

Key Features: Chemical treatment dips, automated mixing system, batch mixing, Wonderware InBatch Software, Class 1, Group D, Division 1, hazardous area

BATCH MIXING | LIQUID:

Viscous Non-Newtonian Micro-susceptible Flammable liquids Toxic fluidsADVANCED BATCH MIXING TECHNIQUES:

Industrial in-tank agitators High shear mixers Scraped blade mixers External re-circulation systems“EPIC offered an in-house construction service where they built modular skids for our blending systems. Six modular units containing two blending vessels each were shipped to our plant and installed with very few problems. In Illinois, we have very expensive construction labor. While this endeavor saved us quite a bit of expense, we found the quality of their delivered product was top-notch, conforming to all ANSI and GMP standards. – Project Manager at Oleo Chemical and Personal Care Products Company